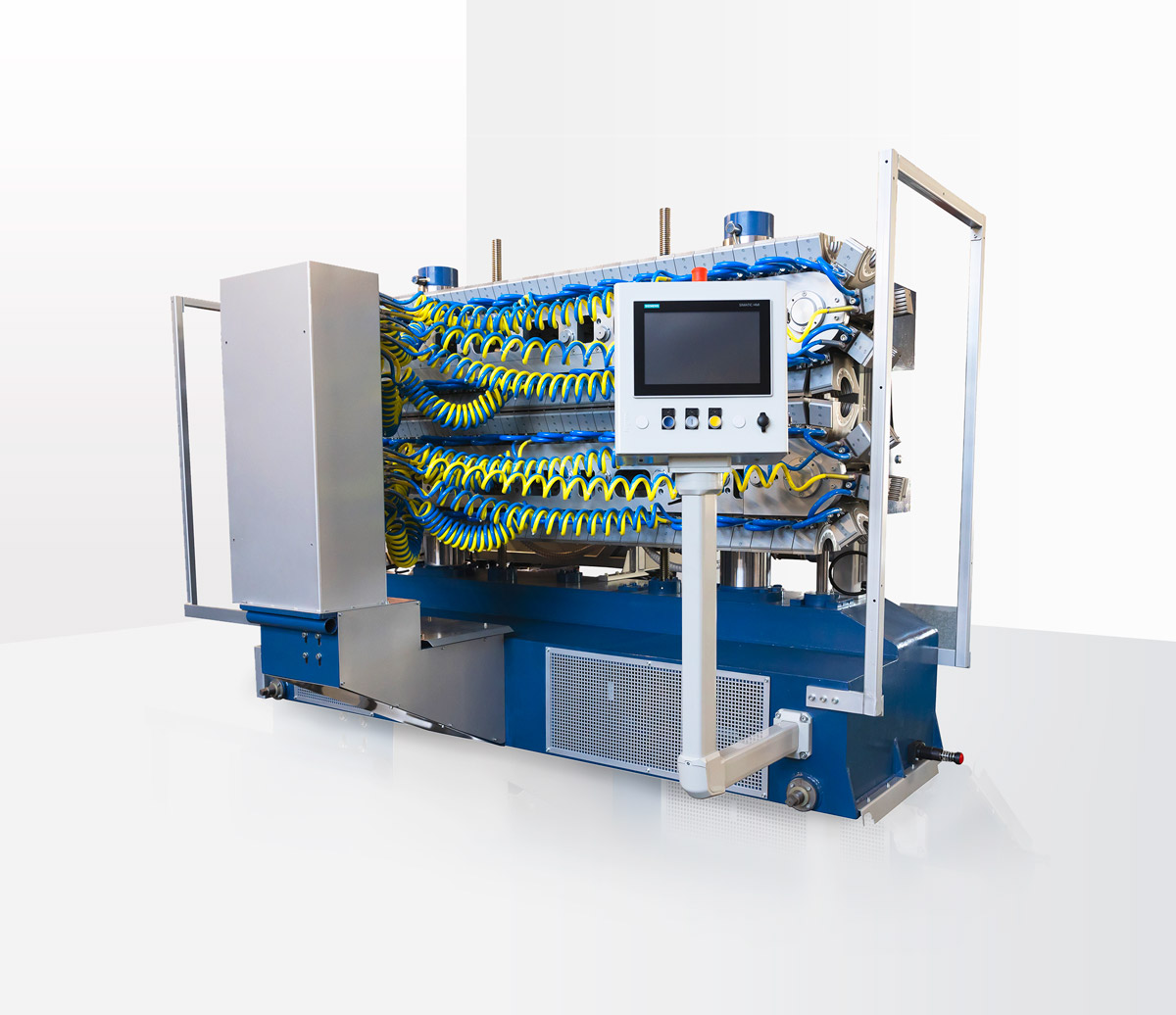

CorrugatorsOlmas corrugators, reliable and highly productive.

Reliable and highly productive, OLMAS corrugators are the result of the combination of Italian expertise and modern international technologies. Characterized by user-friendly operation and low maintenance, our corrugators are made with high-quality materials to ensure long-term durability.

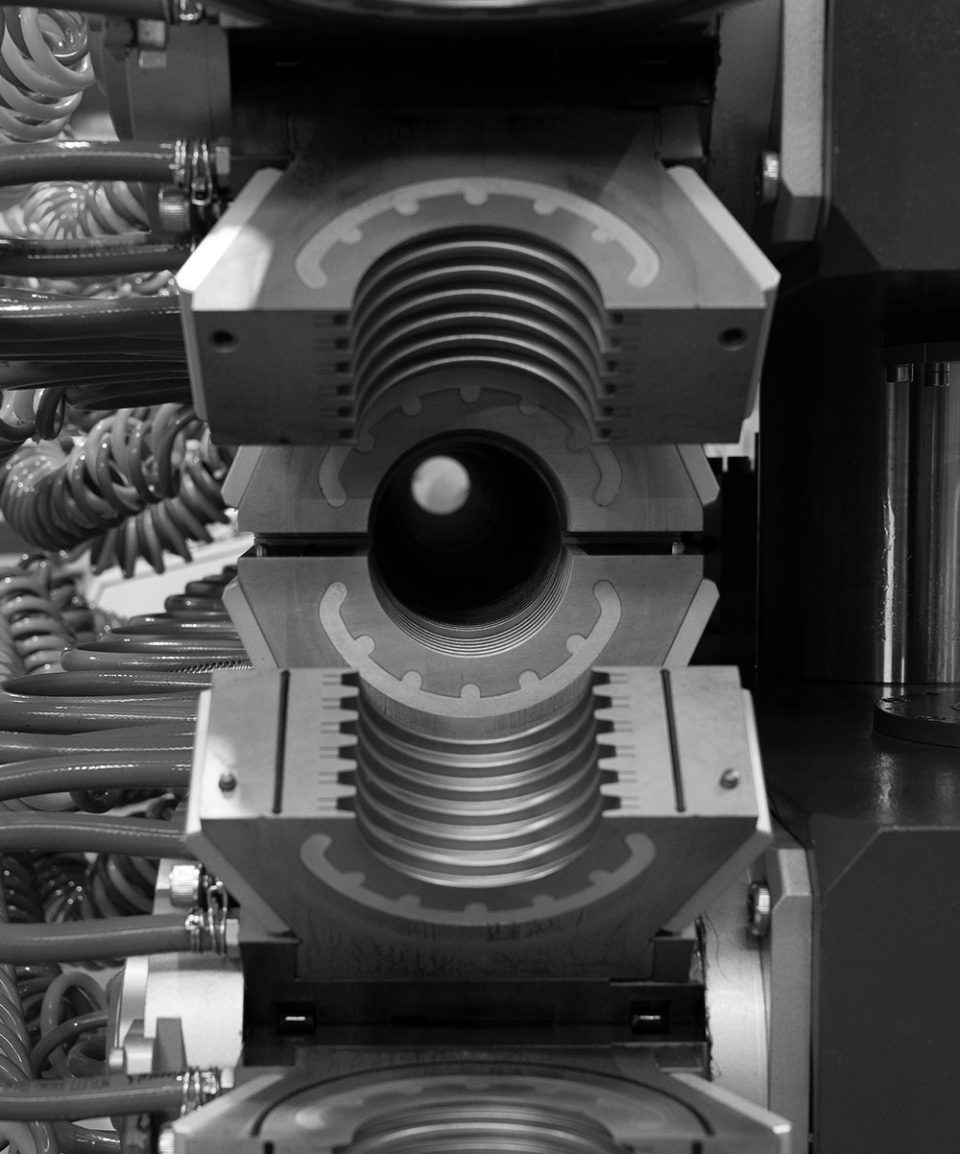

Each OLMAS system is flexible, capable of constantly adapting to different production needs. In versions equipped with PLC and touchscreen monitors, it is possible to continuously monitor the operating parameters of the corrugator and its accessory machines. With a few simple steps, it is also possible to adjust the speed and internal airflow in each segment, allowing the plastic material to perfectly conform to the mold while maintaining a consistent thickness and overall quality of the produced tube.

Moreover, OLMAS corrugators are equipped with external interfaces for controlling or being controlled by other machinery in the extrusion line. Through these interfaces, speed synchronization can be achieved, allowing for variation of production parameters throughout the entire line.